Pololu Zumo 50:1マイクロメタルギアモーターHP [Pololu-998]

販売価格: 3,280円(税別)

(税込: 3,608円)

このギアモーターは、コンパクト (0.94インチ×0.39インチ×0.47インチ)で、高品質、51.45:1のメタルギアボックス付きブラシDCモーターです。Sanyo製のポピュラーな12mmギアモーターに近いものです。

長さ0.365インチ、半径3mmのD型の出力シャフトが備え付けられています。

主なスペックは、

- 6V:625RPM

- 100mAでフリーラン

- 15オンスインチ(1.1kg-cm)

- 1.6Aでストール

■注意点

この商品は、シャフト部分がないためシャフト付ををご希望のお客様はこちらからお求めください。

50:1 Micro Metal Gearmotor HP with Extended Motor Shaft

Overview

These tiny brushed DC gearmotors are available in a wide range of gear ratios—from 5:1 up to 1000:1—and with five different motors: high-power 6 V and 12 V motors with long-life carbon brushes (HPCB), and high-power (HP), medium power (MP), and low power (LP) 6 V motors with shorter-life precious metal brushes. The 6 V and 12 V HPCB motors offer the same performance at their respective nominal voltages, just with the 12 V motor drawing half the current of the 6 V motor. The 6 V HPCB and 6 V HP motors are identical except for their brushes, which only affect the lifetime of the motor.

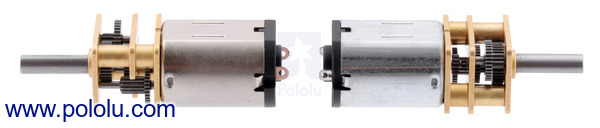

The HPCB versions (shown on the left in the picture below) can be differentiated from versions with precious metal brushes (shown on the right) by their copper-colored terminals. Note that the HPCB terminals are 0.5 mm wider than those on the other micro metal gearmotor versions (2 mm vs. 1.5 mm), and they are about 1 mm closer together (6 mm vs. 7 mm).

|

|

|

Versions of these gearmotors are also available with an additional 1 mm-diameter output shaft that protrudes from the rear of the motor. This 4.5 mm-long rear shaft rotates at the same speed as the input to the gearbox and offers a way to add an encoder, such as our magnetic encoder for micro metal gearmotors (see the picture on the right), to provide motor speed or position feedback.

With the exception of the 1000:1 gear ratio versions, all of the micro metal gearmotors have the same physical dimensions, so one version can be easily swapped for another if your design requirements change. Please see the micro metal gearmotor comparison table for detailed specifications of all our micro metal gearmotors. This dynamically-sortable table can help you find the gearmotor that offers the best blend of speed, torque, and current-draw for your particular application. A more basic comparison table is available below.

Note: Stalling or overloading gearmotors can greatly decrease their lifetimes and even result in immediate damage. The recommended upper limit for instantaneous torque is 35 oz-in (2.5 kg-cm) for the 1000:1 gearboxes and 25 oz-in (2 kg*cm) for all the other gear ratios; we strongly advise keeping applied loads well under this limit. Stalls can also result in rapid (potentially on the order of seconds) thermal damage to the motor windings and brushes, especially for the versions that use high-power (HP and HPCB) motors; a general recommendation for brushed DC motor operation is 25% or less of the stall current.

In general, these kinds of motors can run at voltages above and below their nominal voltages; lower voltages might not be practical, and higher voltages could start negatively affecting the life of the motor.

Details for item #998

Exact gear ratio: 32×33×35×3815×14×13×10≈51.45:132×33×35×3815×14×13×10≈51.45:1

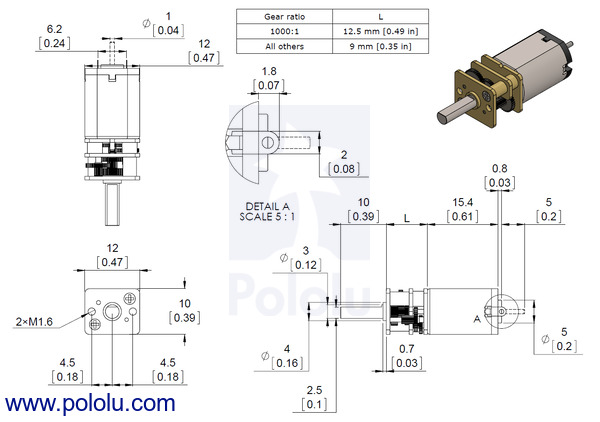

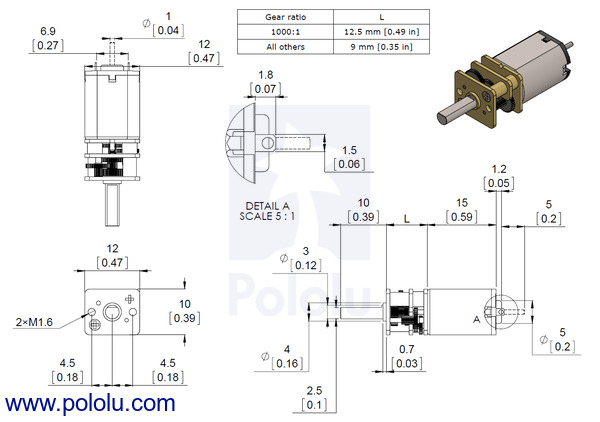

Gearmotor Dimensions

In terms of size, these gearmotors are very similar to Sanyo’s popular 12 mm NA4S DC gearmotors, and gearmotors with this form factor are occasionally referred to as N20 motors. The versions with carbon brushes (HPCB) have slightly different terminal and end-cap dimensions than the versions with precious metal brushes, but all of the other dimensions are identical.

Dimensions of versions with carbon brushes (HPCB)

|

Dimensions of the Pololu micro metal gearmotors with carbon brushes (HPCB). Units are mm over [inches]. |

|---|

Dimensions of versions with precious metal brushes (LP, MP, and HP)

|

Dimensions of the Pololu micro metal gearmotors with precious metal brushes: low-power (LP), medium-power (MP), and high-power (HP). Units are mm over [inches]. |

|---|

These diagrams are also available as a downloadable PDF (262k pdf).

Motor Accessories

- Wheels and hubs: The micro metal gearmotor’s output shaft matches our assortment of Pololu wheels and the Solarbotics RW2i rubber wheel. You can also use our Pololu universal mounting hubs to mount custom wheels and mechanism to the micro metal gearmotor’s output shaft, and you can use our 12mm hex wheel adapter to use this motor with many common hobby RC wheels.

|

|

|

|

12mm Hex Wheel Adapter for 3mm Shaft on a Micro Metal Gearmotor. |

|---|

- Mounting brackets: Our mounting bracket (also available in white) and extended mounting bracket are specifically designed to securely mount the gearmotor while enclosing the exposed gears. We recommend the extended mounting bracket for wheels with recessed hubs, such as the Pololu wheel 42×19mm. Our micro metal gearmotors will also work with our 15.5D mm metal gearmotor bracket pair.

|

|